Nichrome heating wire is an alloy basically of nickel and chromium; it finds very broad applications today in industry and consumer households for high-temperature applications. With its excellent oxidation and corrosion resistance properties, coupled with the capacity to retain its structural integrity at very high temperatures, Nichrome has become a material of choice in many industries. The following blog explains the properties and uses of Nichrome heating wire, outlining reasons as to why it has become an integral material in today’s technological world.

Key Properties of Nichrome Heating Wire

- High Melting Point: Nichrome has a melting point of about 1400°C, making it very useful in various operations around high-temperature endurance applications.

- Resistance to Oxidation: The chromium content in Nichrome forms a protective oxide layer on the surface that prevents further oxidation at higher temperatures.

- Electrical resistivity: Nichrome has a constant and relatively high electric resistivity about 1.10 μΩ•m, whereby it is suitable for converting electrical energy into heat.

- Durability: This alloy works well in harsh environments because of its ability to retain its mechanical integrity and structure under severe stress.

- Non-Magnetic: Since it is non-magnetic, the Nichrome does not interfere with electromagnetic fields; this forms a critical component in certain sensitive applications.

Industrial Applications of Nichrome Heating Wire:

Nichrome heating wire is applied because of its capacity to bear different extreme conditions.

Here are the main uses:

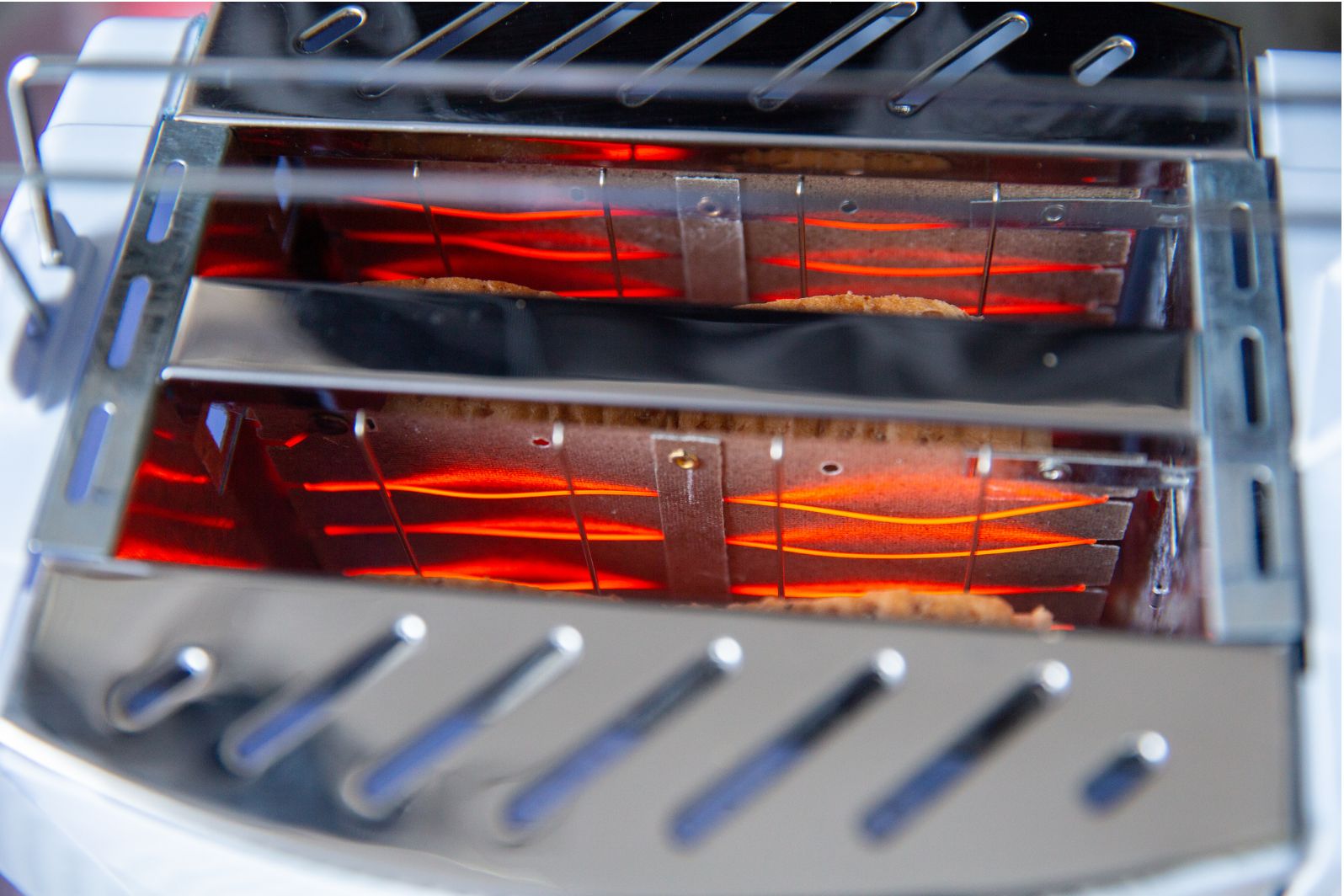

1. Heating Elements

Nichrome is used significantly in the production of heating elements used in industrial furnaces, ovens, toasters, and other appliances. The ability to generate heat without deterioration is inherent in its nature; therefore, it will be quite ideal for such purposes. The heating elements made of Nichrome can work at temperatures as high as 1200°C with effective and perpetual performance.

2. Resistance Heating

Another critical application of Nichrome wire relates to resistance heating. Stable electrical resistivity in this alloy enables it to efficiently generate heat when an electric current passes through the wire. This feature is used most notably in devices such as hair dryers and space heaters, where controlled but intense heating is necessary.

3. The Automotive Industry

Nichrome wire is used in the automotive industry in such component parts as heated seats, defoggers, and rear-window defrosters. Its characteristics allow it to be suitable for this kind of application due to its durability and high-temperature resistance.

4. Aerospace Hardware

Nichrome is further utilised as a component in the aerospace sector since high-temperature stability and durability are required. It maintains its performance due to extreme thermal conditions; thus, this material is utilised in the making of aerospace components.

5. Laboratory and Research Equipment

Nichrome wire is used quite frequently in laboratories for many diverse applications that involve constant and extremely high temperatures normally seen only in furnaces or hot-wire cutters. Its reliability of performance has made it one of the benchmark materials in scientific research settings.

Nichrome 80:20 – The Industry Standard:

Nichrome 80:20 is the most used grade of Nichrome alloy, containing 80% nickel and 20% chromium. This particular alloy design is used where high precision, durability, resistance to oxidation, and corrosion are expected. It possesses strong mechanical properties that enable it to work in strong industrial applications, thus being widely utilised.

Uses of Nichrome 80:20:

- Industrial Furnaces: Nichrome 80:20 is used in the heating elements, due to both their resistance to heat and mechanical strength, which prolongs service life.

- Household Appliances: The alloy is used in various domestic appliances, such as toasters, dryers, electric heaters, etc., where controlled heating properties are essential.

- Automotive Applications: Specific examples regarding heated seats and rear-window defrosters illustrate how Nichrome 80:20 will bend to strenuous requirements in an automotive environment.

- Aerospace components: Nichrome 80:20 is applied due to its stability at high temperatures and durability of aerospace components in contributing toward the reliability of critical systems in aerospace engineering.

Advantages Of Using Nichrome Heating Wire:

- Long Service Life: Nichrome heating elements have a long service life due to their resistance to oxidation and corrosion.

- Efficiency: Nichrome has high electrical resistivity and high thermal conductivity; it efficiently gets heated up with very minimal loss of energy.

- Versatility: Nichrome wire can easily be formed into different shapes and sizes, hence finding applications in very many areas.

- Reliability: Performance consistency of the alloy under different conditions ensures reliable work in critical applications.

Conclusion

The Nichrome heating wire, particularly the Nichrome 80:20 alloy, is a very valuable element in industry and domestic life. In this case, the metal’s ability to resist high temperatures, its durability, and electrical properties uniquely combine to make this material most suitable for use in heating elements and resistance heating, among many other uses. Organisations like Tempsens Instruments (I) Pvt. Ltd. have been at the forefront of delivering quality Nichrome wire for various industrial applications.Whether in your household appliances or the complex machinery of industrial settings, Nichrome heating wire is an important element of technology that keeps our world running today.

- Effective Strategies for Measuring Link Building ROI - February 6, 2025

- The Impact of User-Centered Design in Medical Device Design - January 17, 2025

- Unleash the Art of Captivating Presentations - January 8, 2025